NASA’s Artemis program will land the first woman and the next man on the surface of the Moon by 2024 and enable future crewed missions to Mars. To achieve this, NASA has selected three teams to design human landing systems that will deliver astronauts from lunar orbit to the lunar surface and back. As part of the Dynetics human landing system team, Maxar will deliver a broad range of services and hardware solutions that will enable power, control, communications, robotic manipulation and thermal optimization.

The ability to refuel the human landing system spacecraft and other reusable infrastructure is essential to enabling a sustainable presence on the Moon. To support this, Maxar has developed a novel refueling element concept for NASA’s Human Landing System. The Human Landing System Refueling Element (HLS RE) will act as a mobile gas tanker for the human landing system spacecraft operating to and from the surface of the Moon and could potentially offer refueling capabilities for the Gateway. We spoke with Tiffany de Groot, Maxar’s HLS Program Manager, to learn about the technology, why it matters, and how it can be applied to future missions.

Maxar: What is the Human Landing System Refueling Element?

Tiffany de Groot: Through a NASA NextSTEP Appendix E study award, the agency granted Maxar an opportunity to create an economically viable, long term replenishment solution for human landing systems operating at the Moon. NASA provided us with only one requirement to meet: provide human landing systems with the propellant quantity and type needed to execute at least one lunar sortie per year. With this in mind, it was up to us to formulate an economically viable solution that could be offered as a commercial service.

In response, Maxar’s HLS RE solution includes a reusable transport tug and a standardized fuel tanker that can support a variety of fuel delivery solutions and individual client interfaces. Leveraging Maxar’s design for the power and propulsion element of the NASA-led Gateway, the transport tug collects fuel tankers launched to high Earth orbit and delivers them to client vehicles near the Moon that need refueling. The combined transport tug and tanker form a refueling spacecraft that berths with and refuels client vehicles, extending their mission. You can think of it as roadside assistance in space, similar to in-flight refueling of a jet.

Maxar: What is your role on the HLS refueling element program?

Tiffany de Groot: I’m Maxar’s Deputy Program Manager on HLS RE. In this role, I acted as the glue between our customer, NASA, and our team, providing a roadmap for our design and final product for the program, which falls under NASA’s NextSTEP Appendix E. I work on a team composed of 10 company and subcontract experts in a variety of fields. Because we’re a small team, we all wear multiple hats. In that respect, my role is more like a hybrid between program management, systems engineering, and subcontracts management. All of the team members are very knowledgeable and excited about our work, so we have a great time together!

Maxar: What’s the next milestone for the program?

Tiffany de Groot: Now that the HLS awards have been released, it’s evident that our refueling element solution can play a significant part to make each one of the proposed concepts more efficient and sustainable. Our study findings include a short list of key technologies that warrant a near-term ground or low-Earth orbit demonstration to robustly prepare for a 2024 or 2025 launch of the refueling spacecraft. We can build and launch a fully functional refueling architecture that addresses the 2024 HLS requirements in a way that enables those concepts to become longer term, sustainable solutions.

Maxar: NASA often refers to sustainability as a crucial aspect of their Artemis Program to send the first woman and next man to the Moon by 2024. How does HLS RE enable sustainability?

Tiffany de Groot: We designed Maxar’s HLS RE solution to be adaptable as well as sustainable. The tankers are customizable to support the specific fuel and interface required by the vehicle being refueled, and the transport tug itself is refuelable, enhancing its sustainability and operational life. HLS RE provides NASA with the critical capability to refuel both government and commercial solutions for its Artemis Program, including commercial reusable launch vehicles.

Maxar: Maxar is building the power and propulsion element of the NASA-led Gateway and is also building spacecraft and robotics for on-orbit servicing, assembly and manufacturing. How does the HLS RE fit into this overall space infrastructure?

Tiffany de Groot: The timing has worked out beautifully in that our HLS RE study builds on decades of flight heritage. Our high efficiency solar electric propulsion platforms and robotic systems are enabling flight programs for satellite servicing, exploration to asteroids and the foundation for the Gateway. Each of these flight programs have allowed us to mature the technologies needed to create the infrastructure we’re proposing. We’re simply putting the pieces together in a new and exciting way. We could not offer a 2024 launch of an effective refueling architecture without the groundbreaking work of the teams preceding us. HLS RE is a strong example of how Maxar’s current technology offerings can be used together in different and adaptable ways for a variety of space infrastructure requirements.

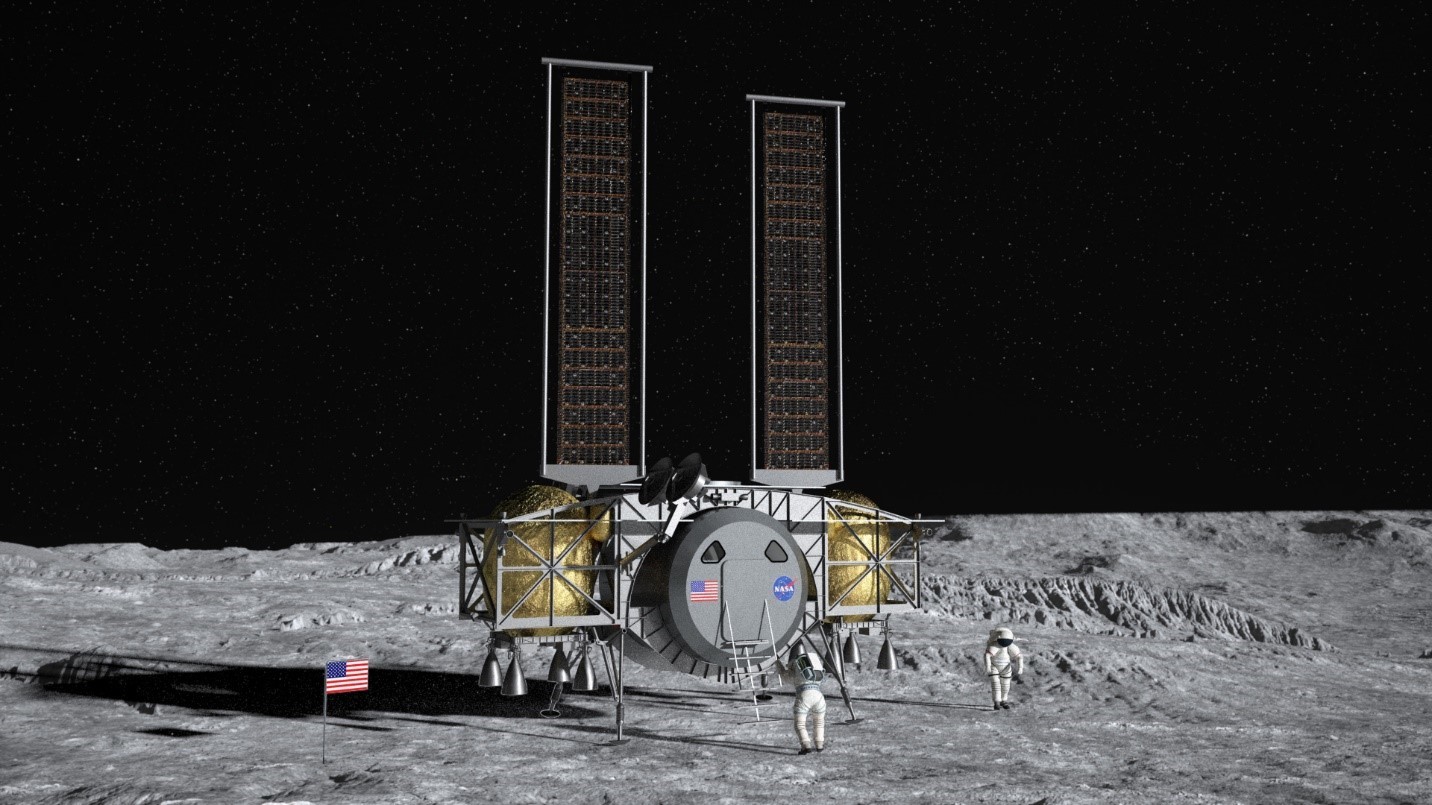

Maxar is supporting Dynetics in designing and building a human landing system for NASA. Image: Dynetics