A few weeks ago I had a chance to visit the newest member of the Maxar family, Neptec (up in Ottawa), which joined the MDA team back in July. I arrived after a fluke tornado hit Ottawa (not my fault!) but fortunately Neptec was unaffected. I was impressed by the smart, focused and scrappy team. It’s a great fit with Maxar, and it blends the energy of a startup with the experience of a quarter-century heritage of building high-performing hardware in space, including contributions to 49 space shuttle and ISS missions.

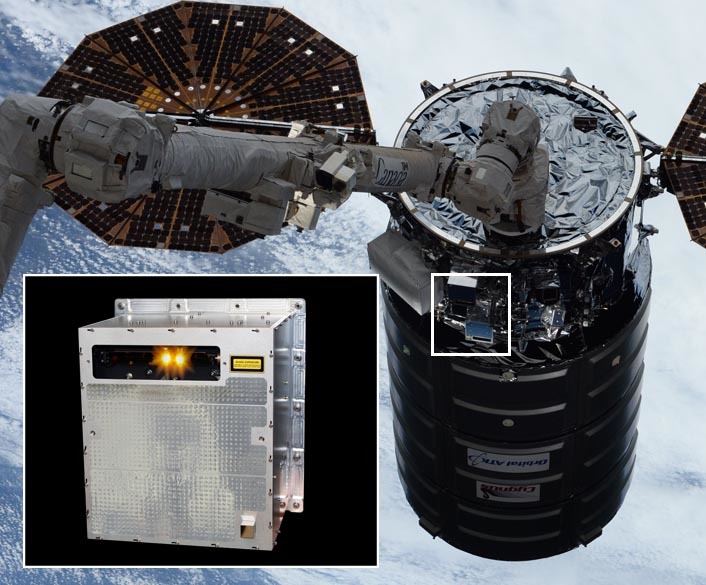

Some of Neptec’s unique expertise lies in the development of space-qualified LIDARs for landers and proximity operations in space. These instruments tell you how far away something is, which is mission critical, since accidentally slamming into a satellite, a space station, or the ground of another planet could make for a really bad day. Because of the Neptec team’s deep understanding of the technology, they are able to produce high performance systems that are extremely cost effective—very New Space. An example is the Tridar system which uses Lidar to form a 3D image and then matches its position against a 3D model; Tridar is the primary rendezvous and docking sensor for the Cygnus spacecraft (cargo resupply to the International Space Station).

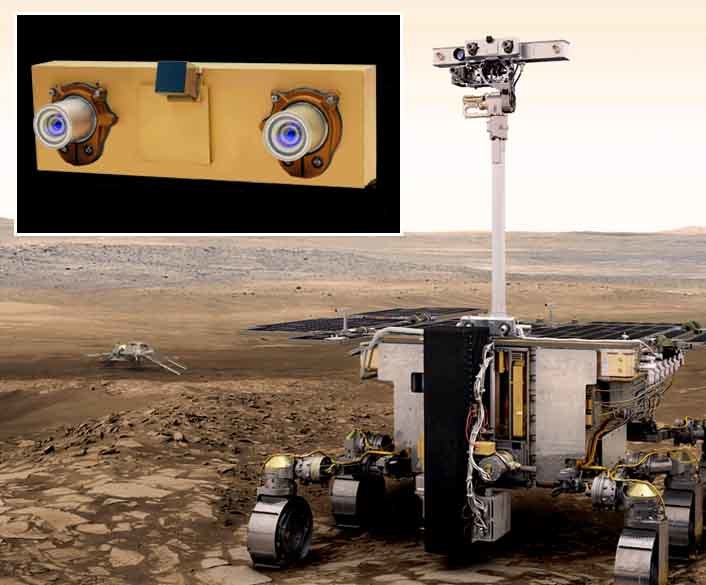

Neptec also produces a range of space-qualified cameras for applications such as robotic arms and planetary rovers, like the ExoMars rover, which will launch in 2020 with a sensor capable of surviving temperatures from -130° C to +125° C and weighing less than 800 grams. Neptec is also building the cameras for the NASA’s Restore-L mission (which Maxar’s SSL is also supporting), including a thermal IR sensor to detect hot spots on a satellite (a key technology for satellite servicing, which I’ll be discussing in my next blog).

Neptec’s laser expertise also lends itself to precision metrology (measurement) systems, such as the one on the joint NASA-JAXA Astro-H mission—a large X-ray telescope. The Neptec instrument measured micron-level deflections in the telescope structure, crucial to being able to maintain imaging performance in this large structure. Then there is the Proba-3 mission where Neptec produces a relative navigation sensor accurate to 100s of microns, enabling space telescopes to be built from a distributed structure. Both types of sensors will be useful as we begin to assemble and deploy larger and larger structures in space in the future (which I will touch on in my next blog post).

And, believe it or not, Neptec is also developing an approach for quantum key distribution using entangled photons. This enables two widely separated parties to generate a shared secret key that they can use for a conventional encrypted conversation, but due to the properties of quantum mechanics, they know that no third party has eavesdropped on the key, making it perfectly secure and avoiding the need to physically distribute keys on media.

This technology will become increasingly important in ensuring secure computer-to-computer communications without the bottleneck of physical key distribution or the vulnerabilities that continue to emerge in conventional cryptographic key exchange techniques.

The new space economy is built around activities like satellite servicing, space mining, on-orbit manufacturing and deep space exploration -- by both humans and AI-powered robots. Maxar companies are involved in everything from designing a next-generation lunar rover for CSA and the power and propulsion element for NASA’s lunar gateway, to developing robotic missions to service satellites in low Earth and geostationary orbits. Neptec has innovative capabilities that will enable many of these projects, expanding our understanding of the universe and making life better for humans on Earth, in orbit and – eventually – on other worlds.